How Bone China is produced?

A standard manufacturing process of Bone China entails the following stages. The Each stage is handled with highly skilled craftsmanship to ensure the finest quality.

(1) MIXING: A body mixture is made with bone ash, feldspar, quartz, kaolin, and ball clay. Among all of the ingredients, bone ash (about 40% to 45% of the mixture) is the key ingredient that enhances whiteness and translucency of Bone China.

(2) FORMING: Forming methods vary depending upon the shapes. Regular round pieces like plates and bowls are generally formed on jiggers, and such irregular pieces as pots and gravy boats are cast in plaster molds. Oval, square, and rectangular pieces are, moreover, cast in two-parted plaster molds to stabilize the shapes. The formed bodies, now called ‘greenwares,’ are left to dry and finished with water sponging to gently remove scratches and scars from the surfaces.

(3) FIRST FIRING (BISCUIT): Differ from the conventional porcelain making, the Bone China’s first firing, called ‘Biscuit,’ is carried out at a temperature of around 1,200 to 1,300 centigrade in the oxidizing atmosphere. This process vitrifies the greenwares and makes them durable, white, and translucent. However, in order to achieve the best results within such specific temperature range, the firing schedule must be carefully controlled. Also, about 20% shrinkage of the greenwares occurring at this stage is apt to cause deformation and cracking. In order to overcome this, most pieces are placed on refractory setters, called ‘cranks,’ to let them follow the profiles of the setters. Those irregular shaped pieces that the on-crank firing does not work are set in saggers.

(4) GLAZING: Bone China’s glaze is a mixture of frit and kaolin. Because the biscuit (the greenware after first-fired) is nonabsorbent, the glaze needs to be applied by spraying.

(5) SECOND FIRING (GLOST): The glaze-coated biscuits are set in the saggers in order to avoid direct exposure to flames. The saggers are piled up on kiln cars and sent into a tunnel kiln. When the temperature goes up to around 1,000 to 1,200 centigrade in the oxidizing atmosphere, the glaze melts and fuses onto the biscuits. All glostwares coming out of the kiln are strictly inspected, and only a few can be passed onto the decorating stage.

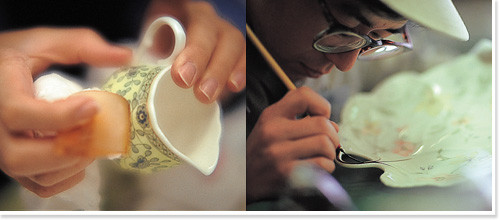

(6) DECORATING: Bone China’s standard decorating methods are spraying, decal transferring, gold finishing, and hand painting. After the decoration, pieces are fired at 700 to 800 centigrade again to make the pigments fuse into the glaze-coatings. Among the mentioned decorating methods, hand-painting is applied only by proficient artisans. Also, gold or platinum finishing is hand-blushed onto the pieces by well-skilled artisans when necessary.